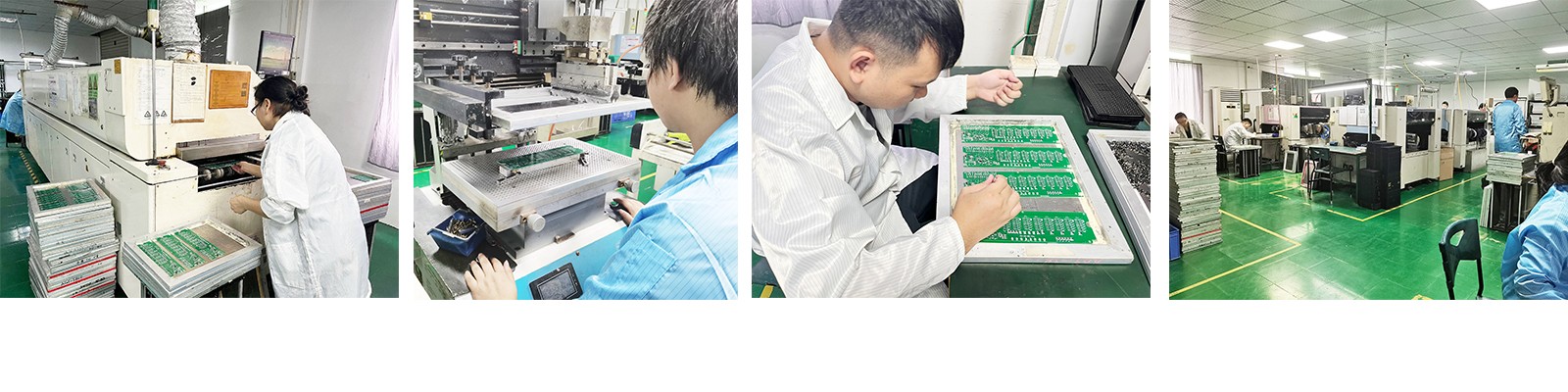

SMT LINE

SMT is very popular process for electronic products. Its high efficiency and high precision can help our devices to be more accurate and reliable

How We Guarantee

SMT WORKSHOP

AOI inspection is particularly important as a checkpoint of SMT, it can help us improve the yield rate of circuit boards to 99.8%.

AOI inspection is particularly important as a checkpoint of SMT, it can help us improve the yield rate of circuit boards to 99.8%.

How We Guarantee

AOI Inspection

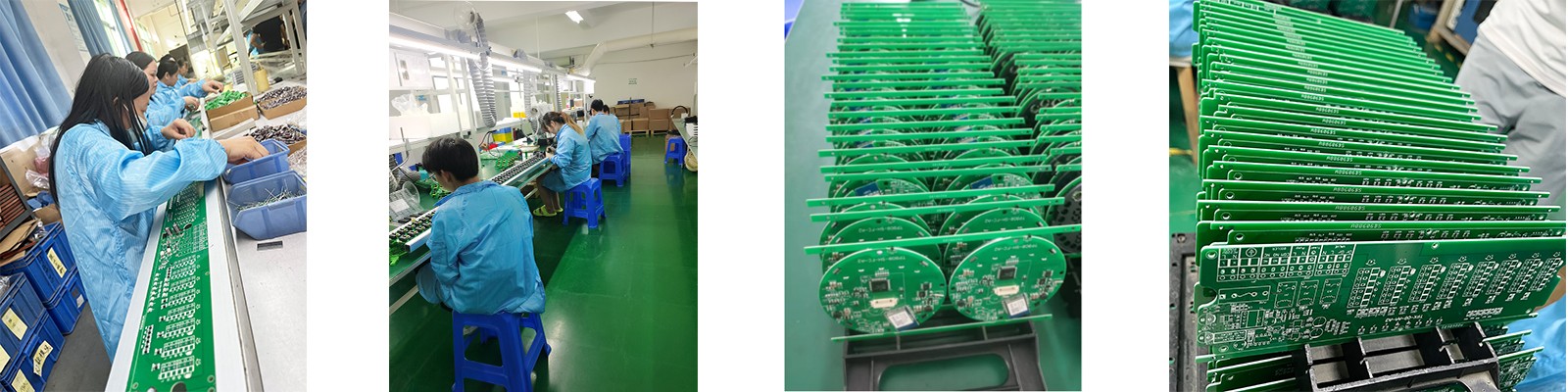

DIP

For a room thermostat, DIP process is necessary for some bigger components that unable to be done by SMT, like relay, large capacitance, and terminals etc.;

People plug in the components to correct position, then through wave soldering machines, that helps all the components fix to the PCB;

Then 100% visual checking and function test on fixture before you can put them neatly on the PCBA rack

DIP Line

Assemble line

We assembling thermostats On production lines, we strictly require employees:

a. Wear anti-static clothing and anti-static wristbands

b. Before assembly, the first piece of the product is checked by PQC to ensure product accuracy

c. Operate according to the work instructions above production line

d. Distinction mark on defective product and good product

e. Take daily maintenance records

How We Produce

Assembly Line

Aging (life Time Testing)

Aging is a mandatory process after the production is finished and before packaging. All Toupwell thermostats are mandatory being aged for 24 or 48 hours (depending on the products) before they're finally packed. The aging facilities include AC or DC source according to the actual products specification. Thermostat different voltages supplies include 12V/24V/110V/230V.

During the aging time.QC will inspect each 2hours to make sure thermostats are all normal.They need record the status on paper.

How We Guarantee

Aging Testing

Packing

Packaging is the last step before shipping however playing an important role for the product performance. Before packing.We need to testing thermostats 100% again.

The QC need to check all details including LOGO.LCD display.Function.Series NO.QC pass.Manual,Screws color box if ODM.To make sure all meet standard .

How We Produce

Packing